Virtual Prototipation: a Revolutionary Design Process

In the field of design and engineering, technological innovation continues to redefine production processes. Among the most advanced solutions in recent years is virtual prototyping, a technology that is transforming the way products are designed, tested, and refined. This article takes an in-depth look at how virtual prototyping is revolutionizing the product development process, with a particular focus on the implementation of these techniques at R.D.D. Italia.

What is Virtual Prototyping?

Virtual prototyping is the process of creating three-dimensional digital models of products that can be tested in simulated environments. Unlike traditional physical prototypes, which require production time and resources, virtual prototypes allow for quick and flexible iterations. This approach enables potential problems to be identified and resolved early in the development process, optimizing time and reducing costs.

The Benefits of Virtual Prototyping for Businesses

The use of virtual prototyping offers a range of measurable advantages for businesses, both in terms of operational efficiency and economic and environmental impact:

Cost reduction: The ability to eliminate or minimize the need for physical prototypes for each design iteration leads to significant savings in materials and labor.

Sustainability: By replacing some manual design stages and reducing the need for physical prototypes, virtual prototyping helps reduce environmental impact. It reduces the consumption of materials and energy used in traditional production processes, contributing to more sustainable practices.

Product optimization: Virtual simulations allow the analysis of product behavior across a wide range of operational scenarios, making it possible to identify critical issues and implement corrections before moving to physical production. This results in fewer defects and greater reliability of the final product.

Technologies Used in Virtual Prototyping

Virtual prototyping relies on various advanced technologies that allow for the simulation of product behavior and optimization of design processes. Key technologies include:

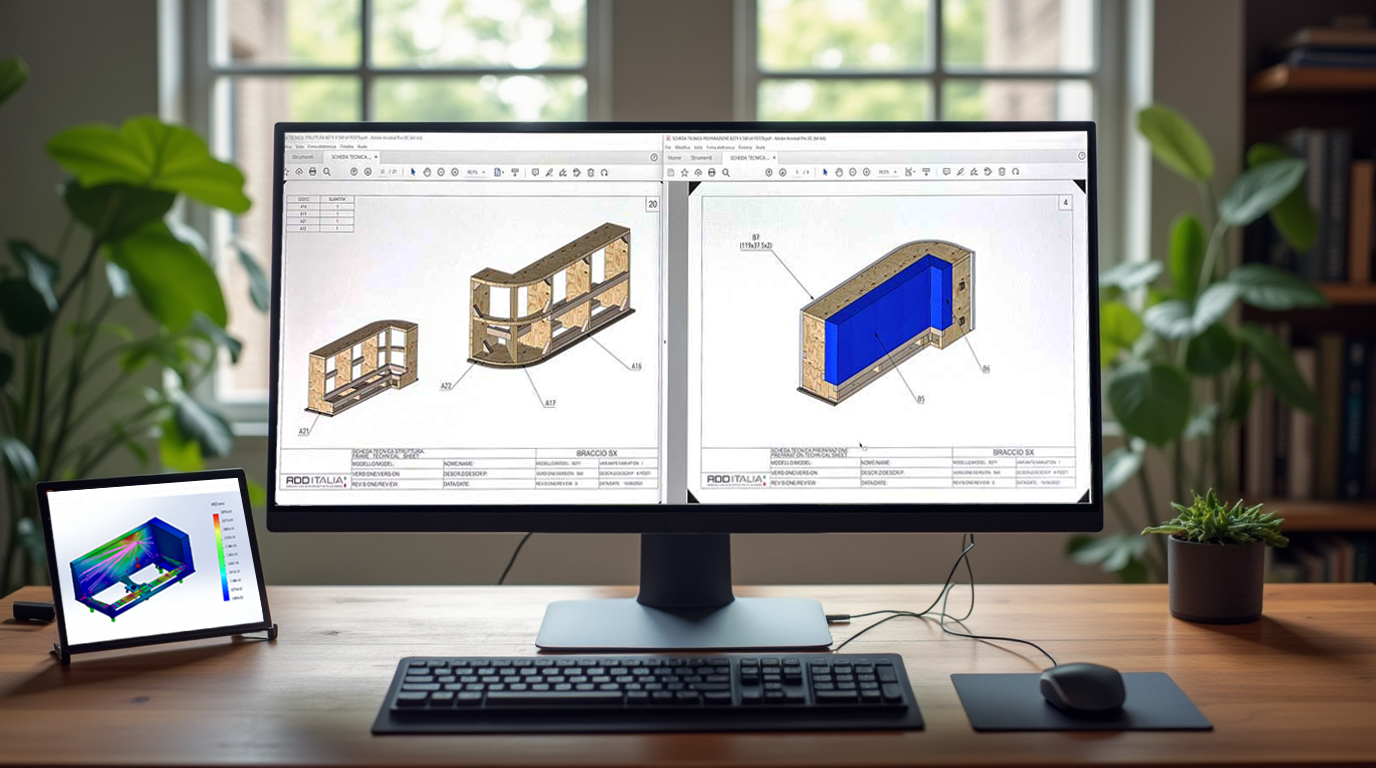

CAD (Computer-Aided Design) Software: This enables the creation of detailed and accurate 3D models that can be viewed, manipulated, and analyzed to assess technical feasibility and performance.

Physical simulations: Simulation software replicates the behavior of products under real operating conditions, such as mechanical or dynamic stress. This helps predict how the product will react in critical situations, reducing the risks associated with physical production.

Applications of Virtual Prototyping at R.D.D. Italia

At R.D.D. Italia, virtual prototyping is a key tool for improving the quality and efficiency of design and production processes. Practical applications include:

Development of mechanical components: We use virtual prototyping to simulate operating conditions and optimize the design of complex mechanical components, improving reliability and reducing validation times.

Design of consumer products: Virtual prototyping allows us to rapidly iterate on designs, evaluating every detail before moving to the production phase, thus reducing the risk of defects or costly changes in later stages.

Conclusion

Virtual prototyping is an essential tool for companies looking to optimize their product development processes. It reduces costs, improves sustainability, and enhances the final product quality. At R.D.D. Italia, we have fully integrated this technology into our workflows, ensuring more efficient, competitive, and environmentally friendly solutions for our clients. For companies operating in increasingly dynamic markets, virtual prototyping is a strategic lever to maintain a competitive advantage and quickly respond to market demands.

Share this post

Latest posts

11 July 2025

11 July 2025